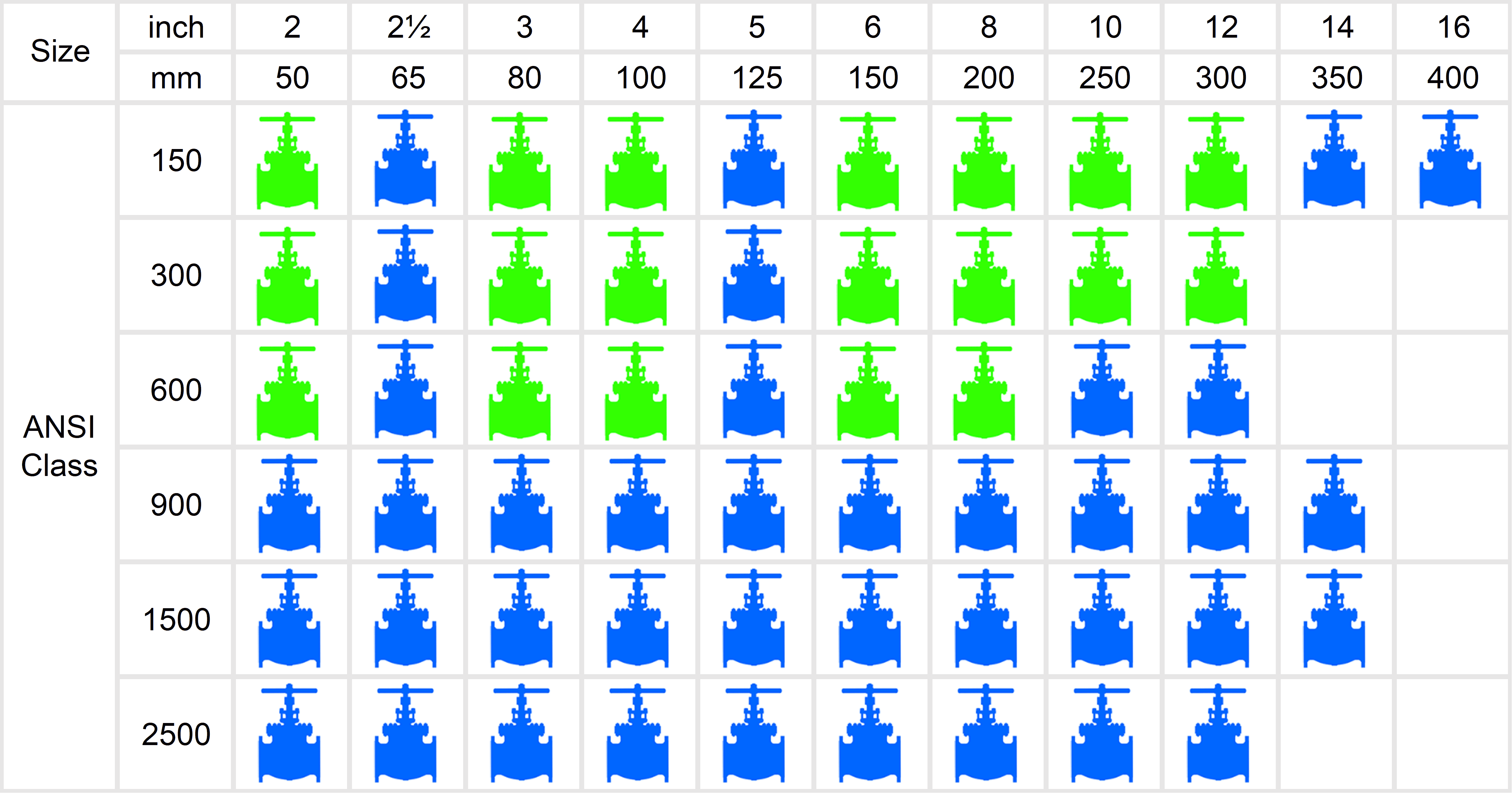

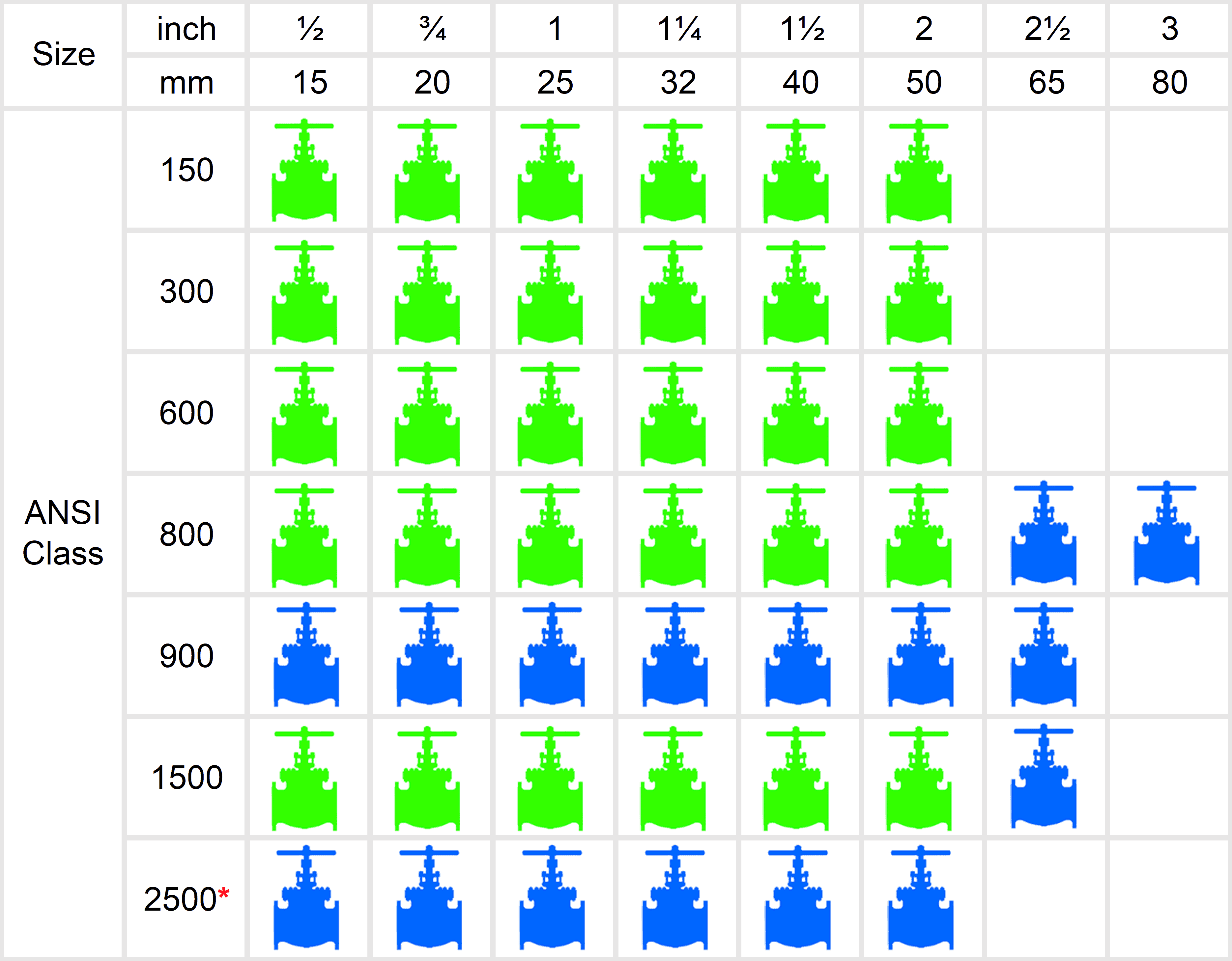

| Kept in stock or commonly manufactured. | |

| Made to order; unlisted sizes available upon request. |

Delta Pacific Valve Mfg. Co. manufactures globe valves from size ½” to 16” in ANSI Class 150 to 2500 pressure ratings. DPV® globe valves are available in straight, angle, and y body patterns, and with plug type, parabolic, and ball type disks. DPV® globe valves are manufactured to BS 1873 and API 602 standards. Bonnet designs include bolted bonnet, welded bonnet, and pressure seal bonnet designs. Body seat designs include integral body seats, threaded body seats, and seal-welded in place body seats. End connections include flanged ends, socket weld ends, threaded ends, and butt-welding ends. Shell materials include ASME B16.34 material group 1, group 2, group 3, aluminum-bronze, titanium, and other alloys.